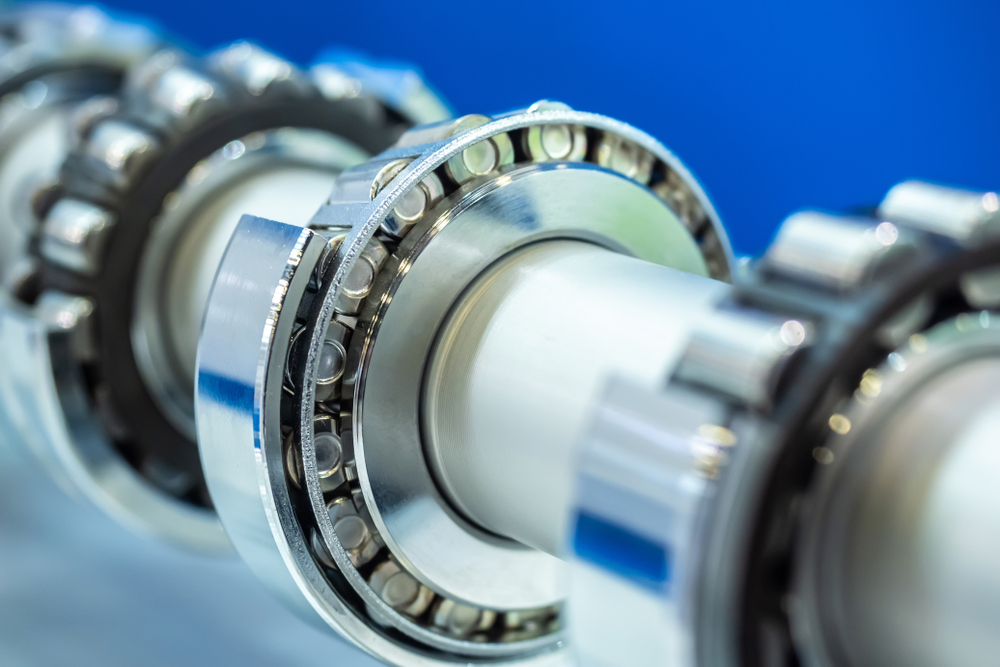

Bearings are small circular components that assist the rotating gear shafts in most electrical machinery, such as electric motors and generators. The gear shaft rotation transmits torque energy to other metal components, enabling the machinery to operate and function.

Electrical machinery must have electrically insulated bearings rather than standard ones without insulation. Since the electric current flows through electrical machinery while in operation, insulated bearings must be in place to block the current and prevent the bearings from suffering damage due to extreme heat and electrical corrosion.

Electrical corrosion can occur when water or moisture comes between two pieces of metal with an electric current flowing through them. It causes an electrochemical reaction that deteriorates the corroded metals and prevents or limits their ability to pass electric current. The result is limited functionality of the electrical machinery and a potential risk of fire.

The Top 4 Benefits of Insulated Bearings

Conventional bearings contain steel balls that are susceptible to rust, corrosion, deterioration, and wear and tear. Plus, without electrical insulation properties, these traditional steel ball bearings are more likely to get damaged inside electrical machinery.

On the other hand, insulated bearings contain non-electrically conductive ceramic balls that will prevent electrical corrosion and all its subsequent effects on electrical machinery. The ceramic balls can resist rust, corrosion, high temperatures, deformation, and wear and tear.

Do you want to know more reasons why you should choose insulated bearings for your electrical machinery? Below are the top four reasons for your consideration.

1) Enable High Efficiency Operations

Insulated bearings are high-efficient bearings because they help increase electrical machinery’s productivity and reliability. Machinery with highly demanding operations like traction motors and generators must have highly efficient bearings to sustain maximum productivity. Otherwise, the machinery will perform poorly for the user.

2) Increase Longevity and Uptime

Insulated bearings can significantly increase the longevity and uptime of your electrical machinery by preventing electrical corrosion. Not only will you be able to use your machinery for extended periods at a time, but your machinery’s overall lifespan will also increase. That means you will not need to replace your electrical machinery as quickly as you would if you had conventional steel ball bearings.

3) Cost Effective and Saves You Money

The number one job of insulated bearings is to prevent electrical corrosion. If you don’t have such a barrier to prevent it, the electrical corrosion will spread onto the metal surfaces of the metal components within your machinery. Increased corrosion reduces electrical flow between two metal points of electric contact, which is why it slows down its operations and ultimately damages the metal components.

Insulated bearings are cost-effective because they prevent electrical corrosion and reduce the need for costly repairs and total replacements of your electrical machinery. You could save hundreds or thousands of dollars by maintaining your electrical machinery with insulated bearings.

4) Reduce Maintenance Duties and Responsibilities

Insulated bearings reduce the corrosion and wear and tear on the metal components of electrical machinery. Because of this, it reduces your maintenance responsibilities and costs because you will not need to clean and lubricate your metal components as frequently.

In fact, insulated bearings increase the lubrication cycle in electric motors and generators because of how much it reduces deterioration and electrical corrosion in the system. That goes a long way toward reducing your maintenance duties over the life of the machinery.

Conclusion

Insulated bearings are necessary for electrical machinery because they block and isolate the electrical currents from flowing within them. This kind of electrical isolation is essential to sustain stable, high-performance operations in your electrical machinery. Without the frequent need to perform repairs and maintenance duties, you can save money and enjoy a longer life with your machinery.